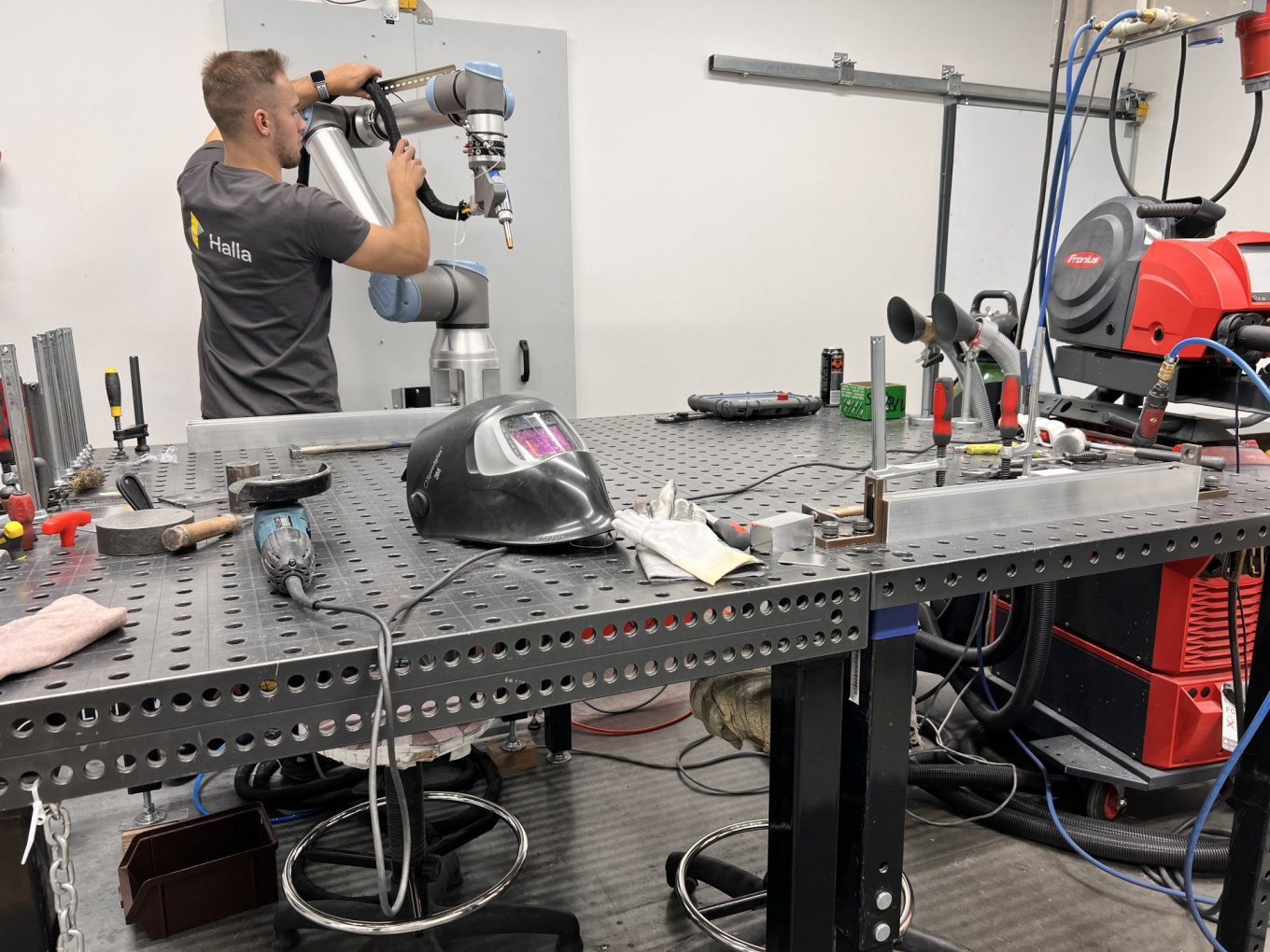

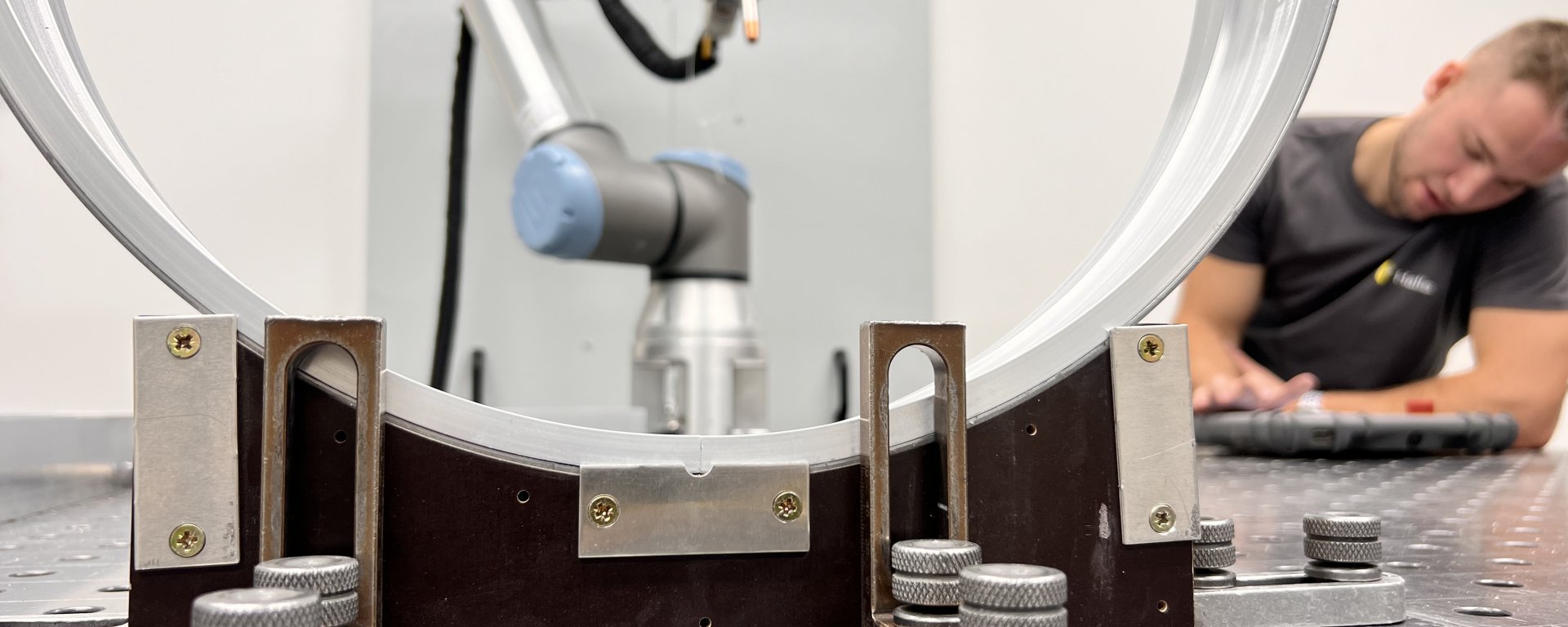

New collaborative robot in production

We have successfully completed the conversion of our welding shop into a mechanical workshop and have newly implemented a collaborative robot into production. This shift in welding and grinding technology is helping us to make our work easier and faster and automate the production process.

The rebuild included enlarging the existing welding and grinding shop to accommodate the cobot. It was necessary to plan the entire space, insert a 3D model of the cobot and prepare project documentation, including fire safety and structural design. The conversion was carried out under full operation. It involved demolishing partitions, building the structure, relocating the Fox grinder, grinding and welding table, and finally installing the ceiling and wiring. We also connected water, waste, air conditioning and central exhaust.

The cooperation between the departments in preparing the space for the cobot was absolutely seamless. We would like to thank all the colleagues who were involved in the rebuild, especially those in the welding, grinding, sawing and bending shops who at times had difficult conditions and less working space.

We look forward to the next steps in automating our production and believe that Kobot will bring many positive changes.

And learn more about synchronising lighting with sport, specifically how European stadiums are illuminated.

Enter your email and we will send you a link to download the whitepaper.

Subscribe to our newsletter. Be informed about news, events we organize or where you can reach us or learn what we are preparing.